Structural steel fabrication plays a crucial role in modern construction projects. Its ability to provide strength, durability, and precision makes it a popular choice for architects, engineers, and builders. In this article, we will explore the importance of structural steel fabrication in construction projects and how it contributes to the overall success of a building project.

The Benefits of Structural Steel Fabrication

Structural steel fabrication offers a wide range of benefits that make it an ideal material for construction projects:

Strength and Durability

- Structural steel is known for its high strength-to-weight ratio, making it a durable and long-lasting material for buildings.

- It can withstand extreme weather conditions, seismic events, and other external forces, providing stability and safety to the structure.

- Steel structures are less susceptible to expansion, contraction, and warping, ensuring the integrity of the building over time.

Flexibility in Design

- Structural steel can be easily customized and fabricated into various shapes and sizes, allowing for greater flexibility in architectural design.

- It enables architects to create unique and innovative structures that would be difficult to achieve with other building materials.

- Steel frames can support larger open spaces, high ceilings, and complex geometries, enhancing the aesthetic appeal of the building.

The Role of Structural Steel Fabricators

Structural steel fabricators are responsible for the production, assembly, and installation of steel components in construction projects. They play a crucial role in ensuring the quality, safety, and efficiency of the building process. Here are some key responsibilities of structural steel fabricators:

Material Procurement

- Structural steel fabricators source high-quality steel materials from reputable suppliers to meet project specifications and standards.

- They ensure that the steel components are fabricated according to the design drawings and engineering requirements.

- Fabricators also conduct quality control checks to verify the accuracy and integrity of the fabricated steel elements.

Custom Fabrication

- Structural steel fabricators use advanced cutting, welding, and shaping techniques to create custom components for the construction project.

- They work closely with architects and engineers to fabricate complex steel structures that meet design intent and performance criteria.

- Fabricators employ precise measurements and computer-aided design (CAD) software to ensure the accuracy and precision of the fabricated steel elements.

The Construction Process with Structural Steel

Structural steel plays a critical role in the construction process, providing the framework and support for the building structure. Here is an overview of how structural steel is used in construction projects:

Site Preparation

- Prior to the installation of steel components, the construction site is prepared to accommodate the structural steel elements.

- Site surveys, soil testing, and foundation work are conducted to ensure the stability and integrity of the building's support system.

- Steel fabricators work closely with construction teams to coordinate the delivery and installation of steel components according to the project schedule.

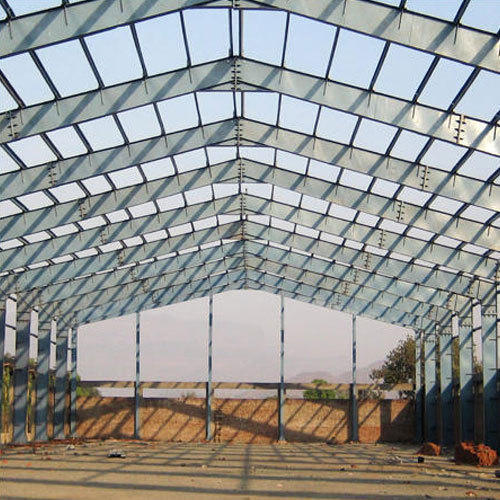

Steel Erection

- Once the site preparation is complete, the steel components are transported to the construction site for installation.

- Skilled steel erectors assemble and erect the steel frames, beams, columns, and trusses according to the construction drawings and specifications.

- Structural steel fabrication allows for fast and efficient construction, reducing overall project timelines and costs.

Finishing and Detailing

- After the steel erection is completed, finishing touches such as welding, painting, and fireproofing are applied to the steel components.

- Structural steel fabricators ensure that the fabricated elements meet industry standards for quality, safety, and performance.

- Detailing work including connections, bracing, and reinforcements is carried out to enhance the strength and stability of the steel structure.