Image Source: Google

Innovation in the manufacturing industry has led to the development of various cutting-edge technologies that have revolutionized the way products are designed and produced. One such technology that is making waves in industries across the globe is polymer laser cutting.

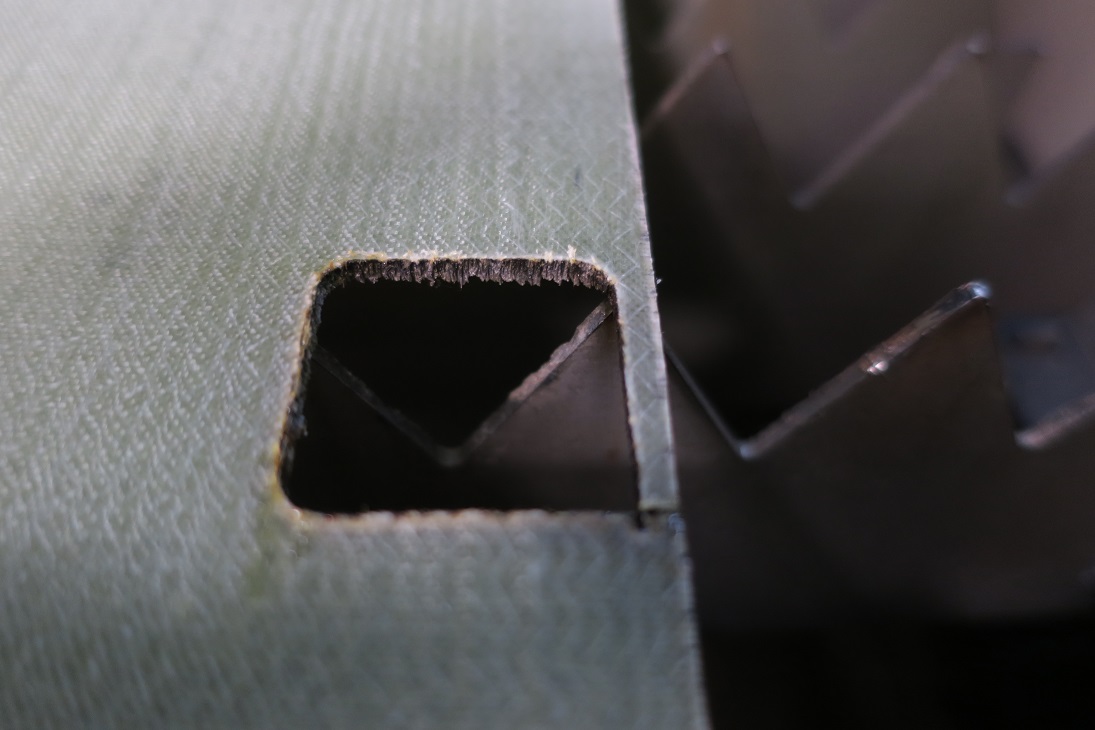

This advanced polymer laser cutting technique uses high-powered lasers to precisely cut through polymer materials with incredible accuracy and speed, allowing for the creation of intricate designs that were once thought to be impossible. In this article, we will explore how polymer laser cutting is reshaping industries and driving innovation in product design and manufacturing processes.

Enhanced Precision and Accuracy

One of the key benefits of polymer laser cutting is its unmatched precision and accuracy. The high-powered laser beams used in this cutting process can cut through polymer materials with incredible precision, allowing for the creation of intricate designs and complex shapes with ease. This level of precision is essential for industries that require components with tight tolerances and intricate details.

Benefits of enhanced precision and accuracy in polymer laser cutting:

- Ability to create complex and intricate designs

- Tight tolerances for precise components

- Consistent quality across large production runs

Increased Efficiency and Speed

Another major advantage of polymer laser cutting is its efficiency and speed. Traditional cutting methods can be time-consuming and labor-intensive, leading to production delays and increased costs. Polymer laser cutting, on the other hand, is a fast and efficient process that can significantly reduce production times and increase overall productivity.

Benefits of increased efficiency and speed in polymer laser cutting:

- Reduction in production times

- Lower manufacturing costs

- Increased productivity and throughput

Wide Range of Applications

Polymer laser cutting is a versatile cutting technique that can be used across a wide range of industries and applications. From automotive and aerospace to electronics and medical devices, polymer laser cutting has found its place in various sectors due to its ability to produce high-quality components with precision and speed.

Applications of polymer laser cutting in different industries:

- Automotive industry for manufacturing precision components

- Aerospace industry for producing lightweight and durable parts

- Electronics industry for creating intricate circuit boards

- Medical devices industry for manufacturing surgical instruments

Cost-Effective Production

While the initial investment in polymer laser cutting technology may be higher than traditional cutting methods, the long-term cost savings make it a cost-effective solution for many industries. The precision and speed of polymer laser cutting can help companies reduce waste, improve product quality, and streamline their manufacturing processes, ultimately leading to cost savings in the long run.

Advantages of cost-effective production with polymer laser cutting:

- Reduced material wastage

- Lower production costs

- Improved product quality and consistency

Conclusion

As technology continues to advance, the adoption of polymer laser cutting is reshaping industries and driving innovation in product design and manufacturing processes. The enhanced precision, efficiency, wide range of applications, and cost-effective production make polymer laser cutting a valuable tool for companies looking to stay competitive in today's fast-paced market.

By leveraging the power of polymer laser cutting, industries can create high-quality products with intricate designs and complex shapes, setting new standards for product quality and manufacturing excellence.